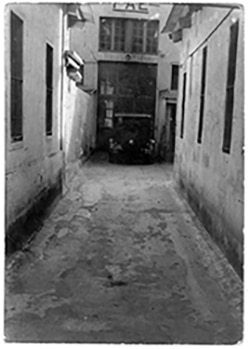

In 1952 Francisco Albero and Rosa Llovensa, my grandparents, had a mechanical workshop in Barcelona. As most workshops were dedicated to replacing damaged components but over time, they realized that they could repair the parts they replaced, leave them as new and sell them to the aftermarket. They had a small cubicle in the back of the workshop where they could fix the pieces between clients. The demand was growing until a time came when they decided to start manufacturing their own pieces. The drawing room was his living room and the factory was his back room. Soon they closed the workshop to be able to dedicate all their efforts to serving the new business. He would design, manufacture and go out to sell the pieces in a van while she would take the numbers of the company and receive the clients. But the most important thing was missing, the name. In this way a small company called FAE was founded.

In less than ten years, they managed to build a team of people as involved as they were in the project and started exporting to the rest of the world. By then, they had already changed premises twice due to lack of space. They’d also doubled the workforce and grown the product range too, though maintaining pressure and fan temperature switches as the brand’s star products. But it wasn’t until 1978 that a young man joined the company who would mark the path of FAE for the next 40 years. My father, Francisco Marro, was in charge of leading the generational changeover that took place in the mid-1980s. He was the one who modernised all the processes by digitalising the company and swapping the pen and paper for keyboards and computer screens. He was the one who decided to invest in R&D, modernising the entire catalogue and specialising in sensors, foreseeing a greater optimisation of vehicle engines.

In the 1990s, FAE took another step forward in its growth and left Barcelona, moving to its current 10,000 square metre facilities in L’Hospitalet. In this new building, a laboratory was built to carry out useful life and quality tests, acquiring new X-ray machines and electronic microscopes to ensure the highest possible performance of parts. A clean room was also built, in which a new sensor was to be developed. Without knowing it, we were laying the foundations of what today is FAE’s star product, the oxygen sensor.

The new millennium brought with it a new production plant in Cervera of more than 9,000 square metres, where we have a plastic injection factory and welding, winding and assembly workshops. This strategic move was made to integrate processes, shorten production times, and control the quality of the entire production chain.

In 2018, we travelled to India to formalise a Joint Venture with one of the most important local automotive companies and the creation of a factory dedicated to the assembly of lambda sensors for motorbikes, supplying a market of more than 20 million motorbikes annually.

70 years after FAE’s founding, those of us who form part of the third generation look back with pride at how the manual press in the back room of the workshop has today become a factory with a turnover of more than 31 million euros, how the engineering department, which today employs 40 people, started in the living room at home, and how the endless van trips around Spain have not only reached India, but also sales in more than 100 countries.

We want to thank all the people who have worked to get us this far and all those who will work to see us through another 70 years.

I only regret that my grandparents are not here to see how far we’ve come, and what we’re going to achieve.

Happy 70th birthday Grandma and Grandpa.

Roc Marro Albero

Head of Communication at FAE