The Exhaust Gas Pressure Sensor is a Differential Sensor measuring the pressure difference between gas in the intake and the outtake of the Particulate Filter. The outtake may be directly set to ambient pressure depending on the model.

This sensor is another element in the pollution regulation systems for Diesel engines imposed by European emissions regulation.

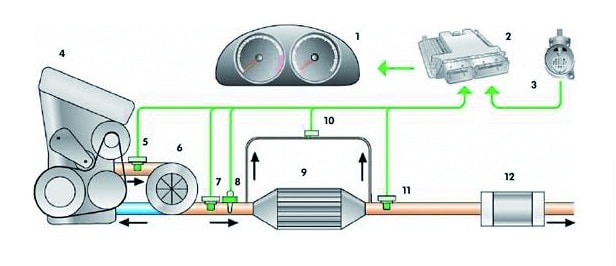

There are currently two different systems where the sensor is found:

Diesel Particulate Filter Systems with additive (FAP):

-

Dashboard Control Unit

-

Engine Control Unit

-

Mass Airflow sensor

-

Diesel Engine

-

Turbo compressor Temperature Sensor

-

Turbo compressor

-

Particulate Filter Temperature Sensor

-

Lambda Sensor

-

Particulate Filter

-

Exhaust Gas Pressure Sensor 1

-

Post-Particulate Filter Temperature Sensor

-

Muffler

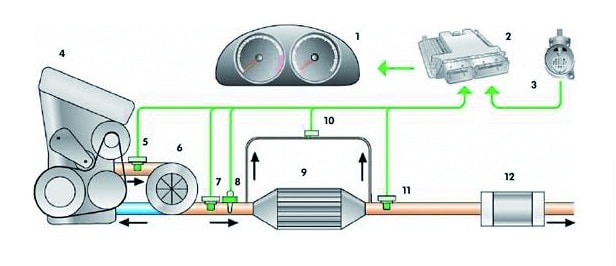

Diesel Particulate Filter Systems with no additive (DPF):

-

Dashboard Control unit

-

Engine Control Unit

-

Additive Tank

-

Additive level Sensor

-

Additive Pump

-

Fuel Tank

-

Diesel engine

-

Turbo compressor Temperature Sensor

-

Turbo compressor

-

Lambda Sensor

-

Oxidation Catalytic Converter

-

Particulate Filter Temperature Sensor

-

Particulate Filter

-

Exhaust Gas Pressure Sensor 1

-

Muffler

-

Mass Airflow Sensor

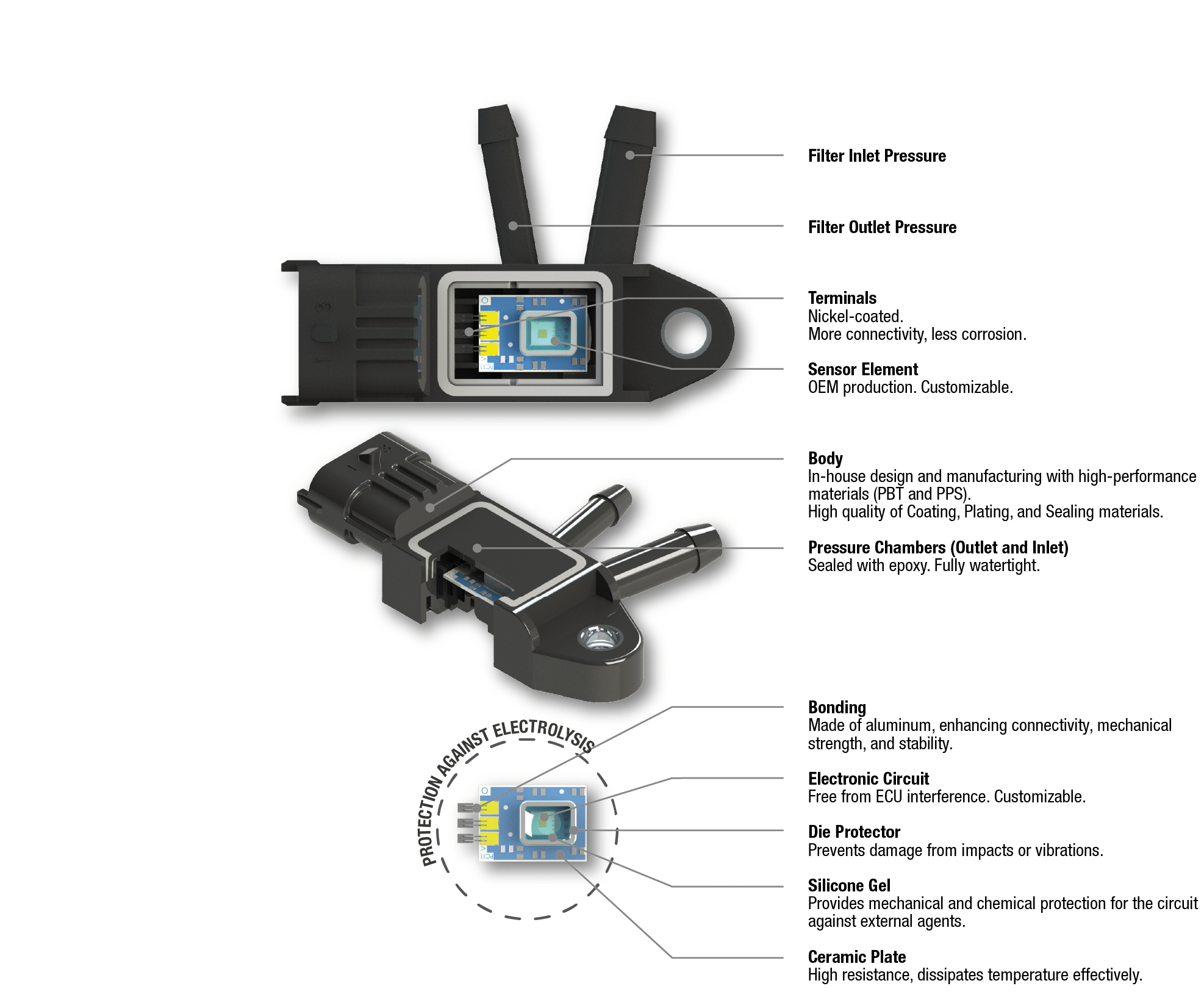

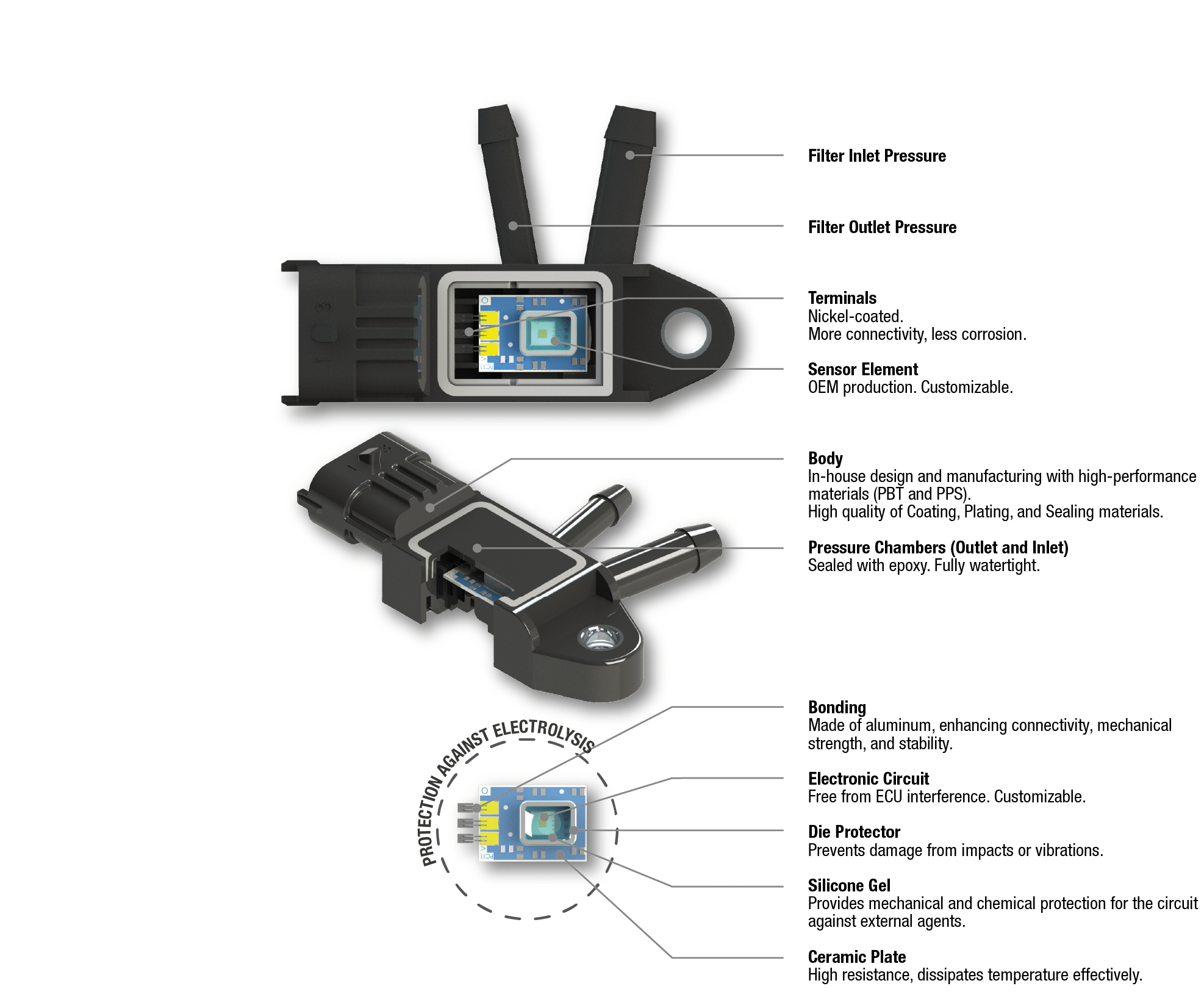

The sensing element of the Exhaust Gas Pressure Sensor is a piezoresistive on in a Wheatstone Bridge configuration. This sensor is basically changing its electrical resistance upon mechanical deformation of the membrane.

The sensing element is integrated in a MEMS die including amplification, thermal compensation and signal conditioning. The embedded digital electronics allows programming of the output signal from 0 to 5V. The die is assembled on a ceramic circuit and the electrical connection is made by wire bonding. The whole system is protected by a receptacle and a silicone gel. The electronics is made by using Hybrid technology and is handled in clean ESD protected room to protect it from unwanted electrical discharges

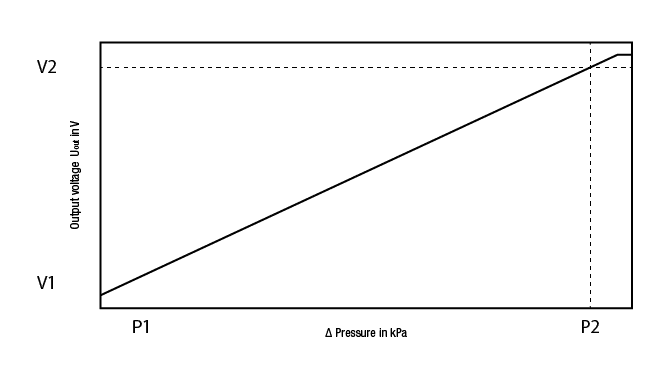

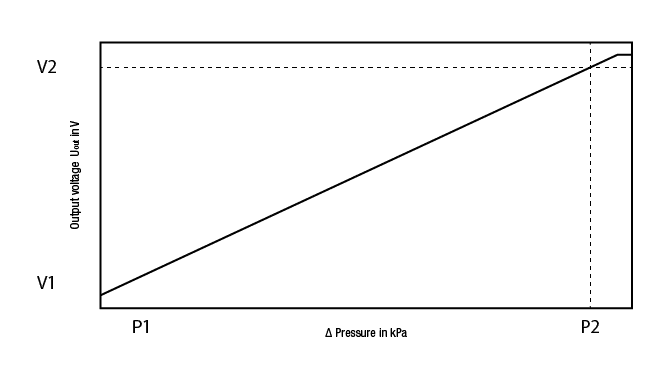

The exhaust pressure sensor output is linear and depends on the pressure difference between input and output. This relationship can be expressed with the following formula:

Graphic data:

| Vout = S*ΔP+Of |

Vout: output voltage (V). |

| |

S: sensitivity |

| |

ΔP: pressure difference between filter input and output (kPa) |

| |

Of: offset |

| |

±400kPa (+30ºC for 5s) |

Technical data:

| – Supply voltage: |

5 V ± 0.5 V |

| – Temperature range: |

-20ºC to 130ºC (within tolerances) |

| – Maximum and minimum temperatures: |

-40ºC to +150ºC |

| – Sensor response time (t 10/90): |

1.5 ms |

| – Maximum pressure: |

±400kPa (+30ºC for 5s) |

All these figures are common for all FAE Exhaust Pressure Sensors. Every part has its specific working curve and tolerances

The Exhaust Gas Pressure Sensor is built with the following components:

- Sensor element: made up of the electronic circuit mounted on a ceramic board

- Body: molded with PBT+30GF, contains all the parts and has two air intakes.

- Pins: tin soldered by automated operation

- Lid: to grant air tightness

The sensor body, the connector and the cable should be checked to ensure that they are in good condition. Also check if the sensor body has any cracks, dents or knocks that could have damaged it.

The sensor body, the connector and the cable should be checked to ensure that they are in good condition. Also check if the sensor body has any cracks, dents or knocks that could have damaged it.

FAILURE CAUSES CAN BE:

- Breaks, pores or cracks in the pipes

- Deterioration of the connection cables or the connector

- Deterioration of the sensor element which will result in an incorrect pressure reading

- Air leakage in the sensor

- Wear in the joints between the sensor and the pipes

MALFUNCTION OF SENSOR CAN CAUSE ANY OF THE FOLLOWING SYMPTOMS:

- Unnecessary filter regenerations

- Power losses if the sensor is not detecting the filter saturation level

- Dashboard light for Particulate filter (or preheating in some models) and blinking light for pre-heating

- Reduction of filter lifespan due to unnecessary regenerations

- Increase in oil consumption

- Increase in pollution levels

Follow these steps to install the FAE Exhaust Gas Pressure Sensor :

- Power off the vehicle

- Locate the sensor (following the pipes coming out of the particulate filter)

- Disconnect pressure pipes (input and output)

- Disconnect sensor connector

- Extract fixation screws or whatever the holding mechanism is Install the new sensor and fasten it

- Connect pipes and electrical connector