Pressure sensors are the sensors that detect the air pressure in the vehicle’s intake and convert it into an electrical signal, which is then sent to the control unit so the stoichiometric mixture or air-fuel mixture can be regulated.

Products

We have what you are looking for

-->

Description

Technical data

Composition

Cause of failure

Mounting

Description

Pressure sensors are the sensors that detect the air pressure in the vehicle’s intake and convert it into an electrical signal, which is then sent to the control unit so the stoichiometric mixture or air-fuel mixture can be regulated.

The importance of these sensors lies in the fact that at higher altitude, with respect to sea level, there is less oxygen in the air. Consequently, the control unit needs to recalculate the amount of fuel injected so it can maintain a balance between the air in the engine and the amount of fuel supplied. This ensures that the emission of pollutants remains within the regulations and the power of the engine is the same at any altitude.

Some sensor models incorporate an NTC type temperature sensor which allows the sensor to detect, not only the pressure, but also the air temperature in the intake. This information is necessary for the control unit to calculate the aspirated air mass and thus regulate the air-fuel mixture.

Pressure sensors must operate in critical installation conditions, they must be capable of operating at temperatures between -40ºC and +120ºC and also be resistant to hydrocarbons. To make this possible, FAE subjects its pressure sensors to exhaustive approval tests that include:

- Cyclic operation at high and low pressure in extreme environmental conditions

- Resistance to vibrations and to impacts

- Overpressure operation at low and high temperature

- Resistance to damp and temperature

- Thermal shock -40 to 150ºC

During assembly, all our sensors are subjected to leak-tightness tests and to output voltage checks. Pressure sensors are located directly in the intake manifold or connected to it by means of a flexible pipe.

Various properties can be used to classify pressure sensors: the pressure range they measure, the operating temperature range, or the type of pressure they measure.

The pressure can be absolute, gauge, normalized relative or differential.

- Absolute pressure sensors measure pressure relative to a reference chamber (close to vacuum)

- Gauge pressure sensors (or relative pressure sensors) are used to measure pressure in relation to the atmospheric pressure present at the time.

- Normalised presion sensors (or constant reference) relative pressure sensors are like relative pressure sensors that measure pressure with respect to a fixed pressure, rather than with respect to the existing atmospheric pressure.

- Differential pressure sensors determine the difference between two pressures and can be used to measure pressure drops, fluid levels and flow rates

Technical data

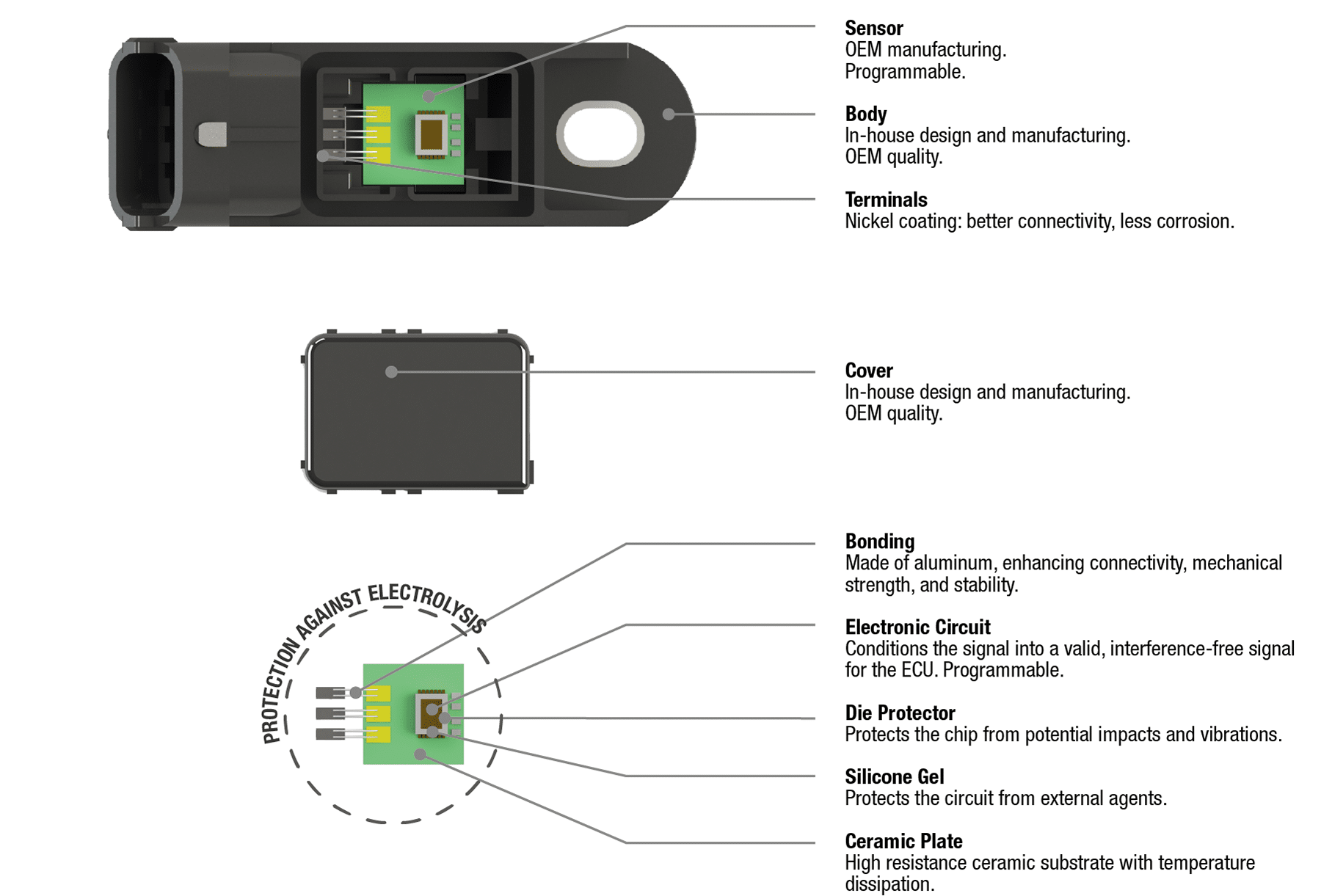

The sensor element of the pressure sensors is the piezo-resistive type with a Wheatstone bridge configuration. This means it varies its electrical resistance according to the mechanical deformation of a diaphragm.

The sensor element is integrated into a MEMS type DIE which amplifies, thermally compensates and conditions the signal. The incorporated digital electronics allows the output signal to be programmed from 0 to 5 V, depending on the requirements that we need for each sensor model. The DIE is mounted on a ceramic circuit and its electrical connections are made by bonding. This is all protected within a receptacle and by silicon gel. The electronic circuit is produced with the use of hybrid technology and it is handled in a clean room due to its delicate nature.

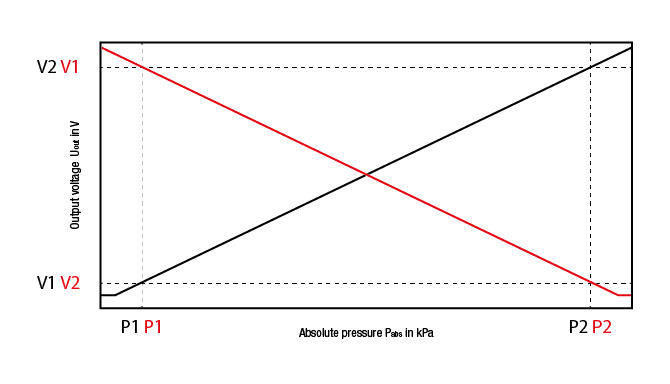

The pressure sensor output has a linear relationship between the intake pressure and the output voltage according to the following equation:

| Vout = S*P+Of | where: Vout: Output voltage (V). S: Sensitivity. P: Suction air pressure (kPa). Of: Offset. |

Technical Data

-Supply voltage………………………………………….5 V ±0.5 V.

-Temperature range……………………………………-20ºC to 120ºC *.

-Maximum and minimum temperatures……………………-40ºC to 140ºC.

-Sensor response time (t 10/90)………1.5 ms.

-Maximum pressure…………………………………………700kPa **.

*(within tolerances).

**(30ºC for 5s).

All this data is common for all the FAE pressure sensors, each specific type of sensor has its operating curve and its specific tolerances

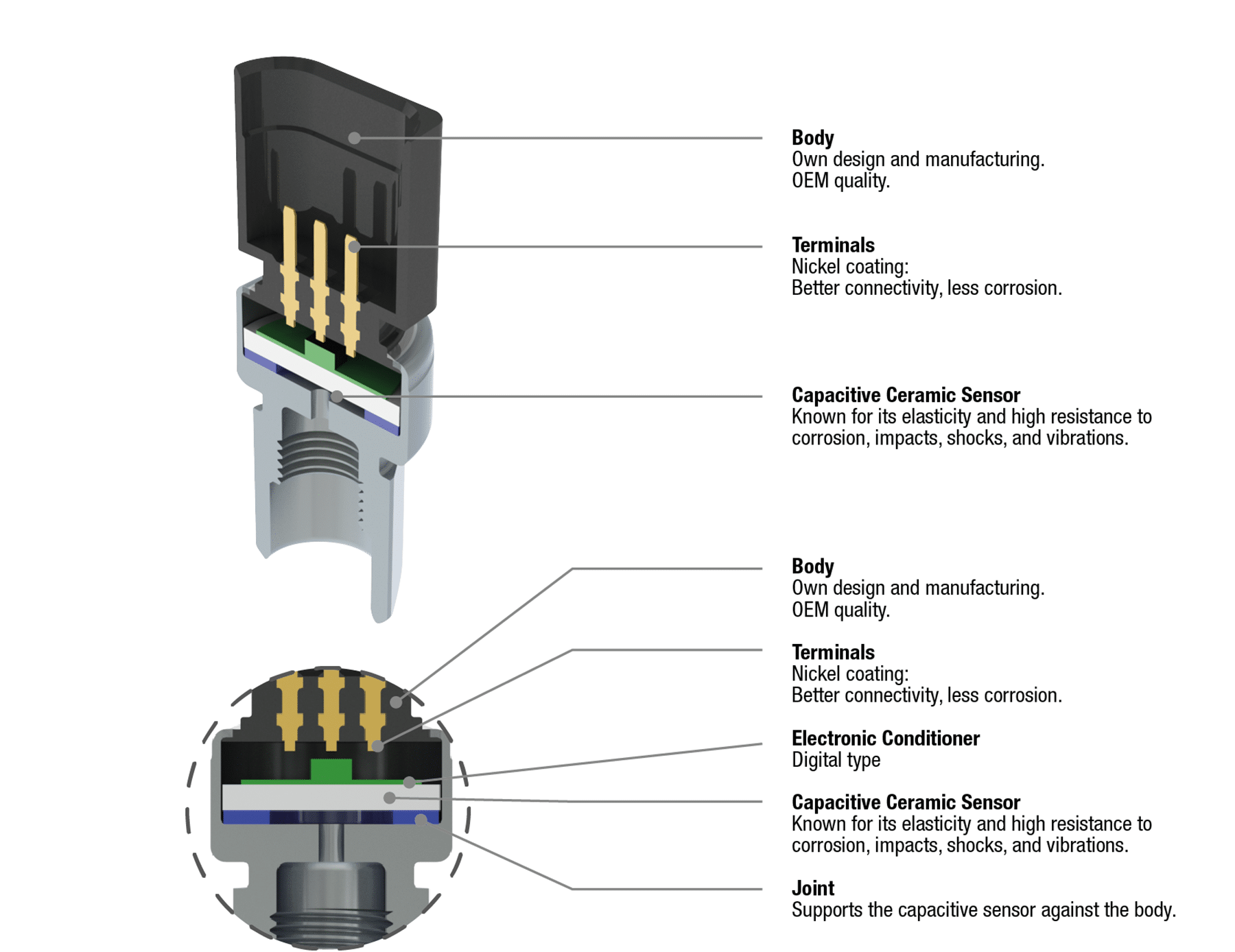

Composition

The pressure sensors are made up of the following parts:

- Sensor element: made up of the electronic circuit mounted on a ceramic board

- Body: generally PBT+30FV, it contains the circuit and terminals. It is normally where the air inlet to the sensor is located (5)

- Terminals: to which the circuit is joined by means of conventional tin solder

- Cover: which may, in some cases, be fitted to the sensor air inlet (5)

Air Conditioning Pressure Sensor

Cause of failure

The sensor body, the connector and the cable should be checked to ensure that they are in good condition. Also check if the sensor body has any cracks, dents or knocks that could have damaged it.

The sensor body, the connector and the cable should be checked to ensure that they are in good condition. Also check if the sensor body has any cracks, dents or knocks that could have damaged it.

Causes of failure may be:

- Deterioration of the vacuum pipes

- Deterioration of the connection cables or the connector

- Deterioration of the sensor element which will result in an incorrect pressure reading

- A leakage problem in the pressure sensor

The possible effects of the malfunctioning of the pressure sensor are:

- Switching on of the check engine warning light

- Difficulty in starting

- Low power or increase in fuel consumption

- Detonation due to excessive advance

Mounting

To change a pressure sensor, take the following steps:

- Locate the pressure sensor in the vehicle (mounted on the intake manifold or fixed nearby)

- Disconnect the vacuum pipe

- Disconnect the pressure sensor connector

- Remove the fastening bolts or its anchoring system

- Install the new sensor and fasten it

- Connect the vacuum pipe

Associated documentation

DO YOU WANT MORE INFORMATION?