ABS Sensors (Anti-lock Braking System) or Wheel Speed Sensors, are mounted in the hub of the wheels and detect the rotational speed of each of them, transferring this information to the ABS control unit. If the ABS control unit detects a substantial drop in speed in one or more wheels, which could cause them to lock, it swiftly intervenes by modulating the braking pressure of each wheel individually. This prevents the wheels from locking and guarantees safe braking, allowing the driver to retain control of the vehicle.

Products

We have what you are looking for

-->

Description

Technical data

Composition

Cause of failure

Mounting

Description

What is an ABS sensor?

ABS Sensors (Anti-lock Braking System) or Wheel Speed Sensors, are mounted in the hub of the wheels and detect the rotational speed of each of them, transferring this information to the ABS control unit. If the ABS control unit detects a substantial drop in speed in one or more wheels, which could cause them to lock, it swiftly intervenes by modulating the braking pressure of each wheel individually. This prevents the wheels from locking and guarantees safe braking, allowing the driver to retain control of the vehicle.

The ABS sensors provide information not only for the system itself, but also for such other systems as the gearbox, satellite navigation systems, the TCS or ASR (Traction Control Systems), chassis control systems, the ESP (Electronic Stability Program) system or the incline control system, which likewise make use of it.

Types of wheel speed sensors

Given the constant development of such sensors, there are today various different designs depending on precision, size and robsutness requirements.

FAE divides these sensors into 2 major groups:

Passive ABS sensors. For toothed wheels.

- Inductive ABS

Active ABS sensors. For wheels with magnetic coding/toothed wheels.

- Hall ABS

- Hall ABS with magnetic coder ring

- Magneto-resistive ABS

Technical data

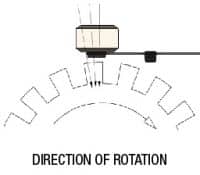

Passive ABS sensors. For toothed wheels (Inductive)

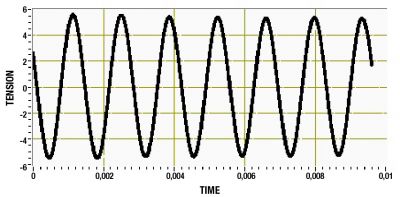

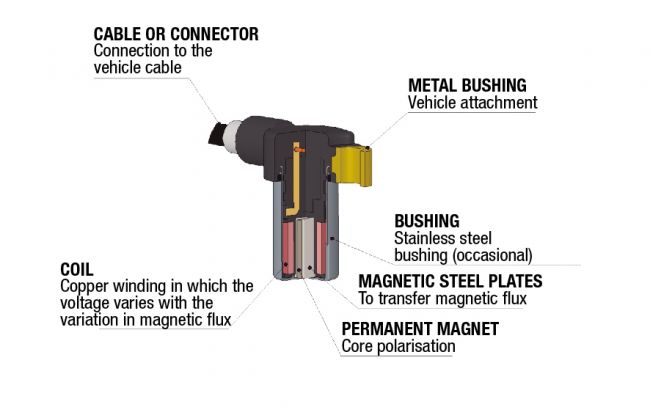

Passive ABS sensors are typically larger and do not begin to function until the wheel reaches a set minimum rotational speed. They comprise a coil wound around a magnetic core and a permanent magnet. The magnetic flow generated between the teeth and troughs of the wheel induce a sinusoidal output voltage proportional to the speed of the variations detected by the sensor. The voltage varies in accordance with the speed of rotation and the gap separating the toothed wheel, in both frequency and amplitude. These variations allow the following to be derived from the signal:

Passive ABS sensors. For toothed wheels (Inductive)

Active ABS sensors are so named because they require an external power input in order to operate.

The operational principle is based on the so-called Hall effect, which comprises the generation of a voltage (the Hall voltage) transversal to the direction of the current in a conductor, when the action of a magnetic field is applied perpendicularly to it.

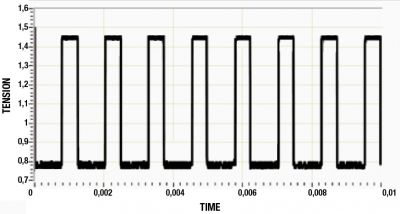

ABS Hall

These sensors are highly accurate and must be installed with great precision. They use a semiconductor sensor coupled to an electronic circuit protecting the sensor from possible voltage spikes, and a permanent magnet. The operating principle is based on the so-called Hall effect, which consists of the generation of a transverse voltage (Hall voltage) to the direction of the current in a conductor, when the action of a magnetic field is applied perpendicularly to it.

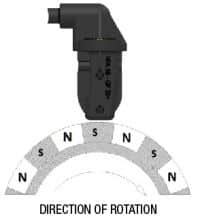

Hall ABS with magnetic coder ring

This shares the same principle as the toothed wheel, although the variation in the magnetic field is caused by the change in polarity of a sectionally magnetised wheel (coder disc). No permanent magnet is fitted, thereby reducing the size of the sensor. Space can be saved by fitting the magnetic ring within the wheel bearings.

Magneto-resistive ABS

Magneto-resistive sensors are scarcely sensitive to their position, which means that they can be positioned relatively far from the coder disc, and still transmit a reliable signal. These sensors allow a highly precise signal to be detected.

Magneto-resistive sensors are scarcely sensitive to their position, which means that they can be positioned relatively far from the coder disc, and still transmit a reliable signal. These sensors allow a highly precise signal to be detected.

The sensor is mounted above a magnetic coder, its resistive properties varying in accordance with the magnetic field presented to it. As a result of the variation in the internal resistance of the centre, the velocity and direction of rotation can be established.

Composition

Passive ABS sensors. For toothed wheels (Inductive)

Active ABS sensors. For toothed/magnetic wheels

Cause of failure

COMMON ABS SENSOR FAILIRES

The outer body, connector and cables must be checked, together with the bushings, to ascertain they are in good condition.

Also check whether the detector reveals any cracks, dents or impacts which could have damaged it. It should be borne in mind that in general a visual inspection is not sufficient to establish whether the part is functioning correctly or not, although it will help to make an initial diagnosis.

-

Cracks or breaks. Tension caused by mechanical stress.

-

Deformation and denting. Overheating of the sensor.

-

No signal. Cable broken by friction or excessive vibration, short-circuits, internal sensor breakage caused by mechanical or thermal stress.

WHEEL SPEED SENSOR FAILURE SYMPTOMS

-

The ABS indicator lights up.

-

Wheels lock during normal braking (only on cars with an electronic braking distributor).

WHEEL SPEED SENSOR MAINTENANCE

The wheel speed sensors are the components subjected to the greatest loads within the braking regulation system.

They prevent the wheels from skidding and are responsible for ensuring stable vehicle road performance.

Check the specific sensor values during each service or every 25.000 km.

Replace if the functional checks are no longer within the specified threshold values.

Mounting

Associated documentation

DO YOU WANT MORE INFORMATION?