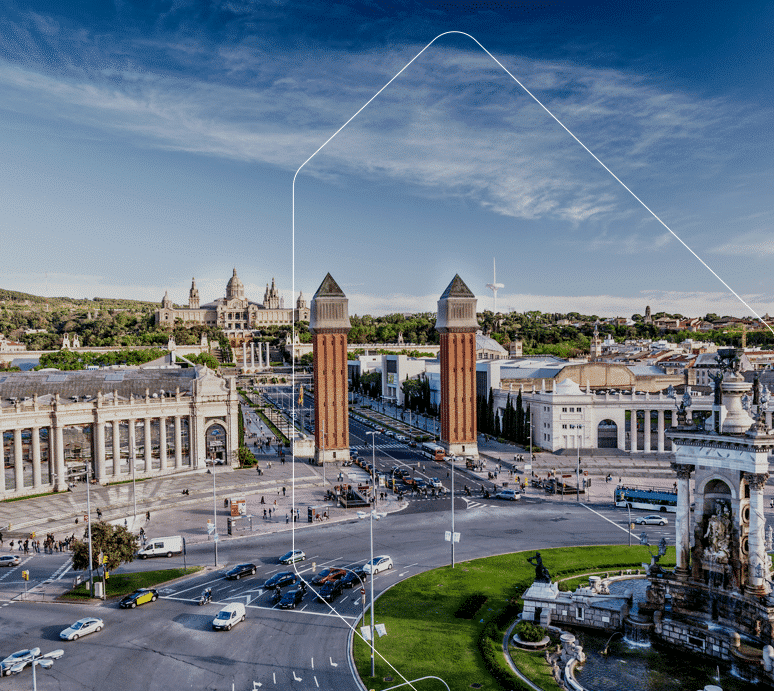

More than 4,000 m2 DEDICATED TO INNOVATING, MANUFACTURING AND DELIVERING SOLUTIONS

At FAE we have two production centers, in Barcelona and Cervera, where the engineering departments and laboratories, as well as the manufacturing and distribution sections, are located.

Clean Room

Our 700 m2 ISO-7 type Clean Room is dedicated exclusively to the processing of flexible substrates, such as multilayer ceramic technology that is applied in electronic ceramics (gas sensors). It allows from the obtaining and processing of ceramics or polymeric films, to the implantation of electronic circuits, in an environment with strictly controlled environmental parameters. We also have a chemical laboratory in which we develop our own formulas for the manufacture of substrates and thus control the entire process and conversion of materials internally.

ESD Room

We also have an ESD (ElectroStatic Discharge) Room of 180 m2, with dissipative flooring, intended solely for manufacturing our electronic components, among others, pressure sensors, exhaust gas pressure sensors and GPS (Gear Position Sensor).

Engineering and innovation

Our R+D+i team, made up of engineers with doctorates in mechanics, electronics, chemistry and industry, is in charge of developing the solutions that have made us leaders in the market. To do this, it has cutting-edge technology, obtaining relevant results in the various areas of its research, such as nanomaterials, biochemical sensors and advanced sensors, or smart textiles.

250

new references in the last 3 years

+4500

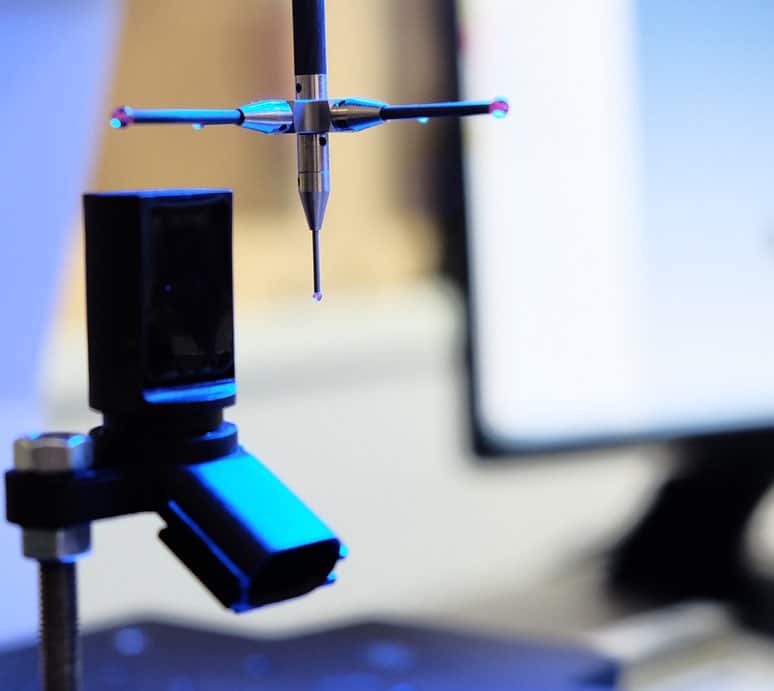

Test laboratories

Our 250 m2 test laboratory is exclusively dedicated to the approval of our products based on automotive standards. In the same way, for the manufacture of special and/or personalized products, we apply the criteria defined by the client.

We have a machining department where we manufacture our machinery, which allows us to optimize our needs more quickly and flexibly, while ensuring better control of the product during checks.

Production

In the production section we have our own control software, a multi-format system suitable for each type of piece, barcode labeling and laser engraving. We pack FAE, bulk (in bulk), or customized to the client according to their specifications.